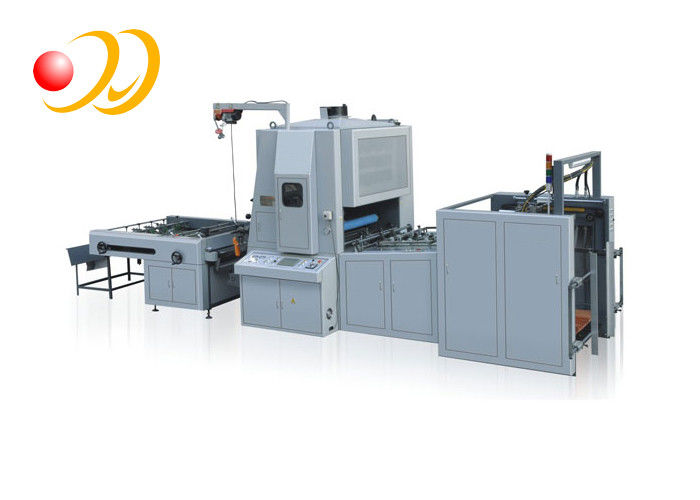

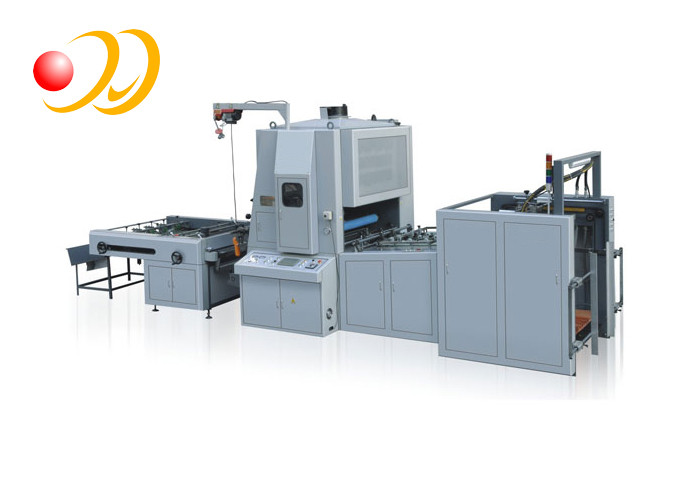

Functions:

BLFM-1100 Vertical Semi-automatic BOPP&PVC film laminating machine (with separating machine), it is multi-functional and widely used for water-based film, oily film, glueless film, pre-glued film. It is simple to operate and easy to maintain, which is suitable to process post-printing books, other publications,wall surface, handbag,color box,color cartons etc. The frequency converter controls the speed, PLC control,

man-machine interface display. It is made of paper feeder, front guide , pull lay, film supply, water-based or oil coating structure, power control for the film, film cutting and punching, hot pressing composite and composite clutch system, roll elimination mechanism, separating part.

BLFM-1100 Vertical Semi-automatic BOPP&PVC film laminating machine, a set of water-based glue, oil-based glue, precoated film as one of the multipurpose models. Easy operation and simple maintenance. wildly used in teaching materials, books and other publications, wall painting, bag, box and color box printed on the surface processing. This machine adopts frequency control, PLC centralized control,HMI display. By the automatic feeder, the former regulations, regulatory pull,wheel brush dedust, oil heat roller in addition to the powder, the film supply,water /oil coating device, hot pressure composite and composite clutch control system, unfolding device, separating unit non-stop stacker and so on, Printed productions pass unfolding device, separating unit, turm to single printed production, After delivery unit to collect into a pile, into the next processing procedures.

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!