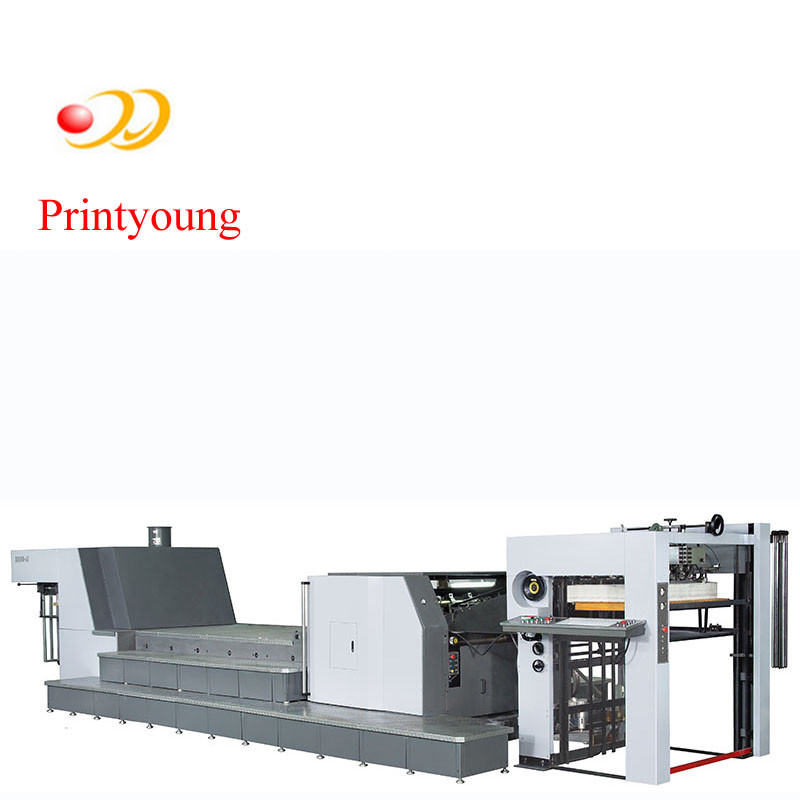

Carton Box Flexo Printing Glazing Machine WIth Ceramic Anilox

Quick Detail

The machine is applicable to ornament of the print with different thickness as large as 720x1040mm, oiling by anilox roller, features even glazing layer, high gloss etc. Thanks to the preciseness of partial glazing and overprinting, the print will turn out to be brighter and fresher in color with characterized as antiwear, dampproof, heat-resistant and anticorrosive.

Combination series of ZMG104 flexographic glazing machine

| Technical parameter function, configuration |

Model of Machine |

| ZMG104 |

ZMG104-UV |

ZMG104-IR |

ZMG104-UV/IR |

ZMG104-UV-L |

ZMG104-IR-L |

| Max. paper size |

720×1040mm |

| Min. paper size |

390×540mm |

| Max. printing area |

710×1040mm |

| Acceptable thickness |

0.10~0.6mm |

| Feeder pile height |

1150mm |

| Delivery pile height |

1100mm |

| Highest printing speed |

sheets/h |

| Solidification/drying capacity (200line anilox roller) |

|

sheets/h |

sheets/h |

sheets/h |

sheets/h |

sheets/h |

| Function Ink supply of anilox roller (optional line No. of anilox roller) |

Flexographic plate partial glazing |

| Printing |

| |

UV solidification |

IR drying

|

UV solidification IR drying |

UV intensified solidification Lengthened |

IR intensified drying Lengthened |

| Configuration module |

Paper delivering |

| Flexo printing with anilox roll |

| |

solidification |

|

UV solidification |

|

| |

|

IR drying |

UV intensified solidification |

IR intensified drying |

| |

|

Extended module |

| Paper collecting |

| Main application |

Pre-printing of flexographic plate |

| Waterborne adhesive printing |

| Partial and solid plate print oil glazing |

| |

UV glazing oil solidification |

Waterborne glazing oil drying |

UV glazing oil solidification Waterborne glazing oil drying

|

UV glazing oil solidification Intensified high speed

|

Waterborne glazing oil drying Intensified high speed |

| Specifications(L×W×H) |

7270mm |

7270mm |

8286mm |

9302mm |

9302mm |

9302mm |

| 3400mm |

| 2100mm |

| Total power |

17kw |

55kw |

45kw |

85kw |

56kw |

70kw |

| Net weight(kg) |

≈9500 |

≈10800 |

≈10300 |

11600 |

≈11400 |

11000 |

| Gross weight(kg) |

≈11600 |

≈13100 |

≈12600 |

14100 |

≈13900 |

13500 |

The other characteristics of the machine

1 Adopting light, machine, electricity, pneumatics integrated control technique including frequency-conversion stepless speed-regulation, PLC programme control, pneumatic cylinder clutching, photoelectrical paper feeding detection etc., the machine is of very high automatization and easy for operation.

2 The moveable oil mechanism features good rigidity, larger replacing room of the anilox roller and easy for operation.

3 A great number of configurations available for customer’s choice, such as UV and intensified UV light solidification, infrared and intensified infrared drying, heat air drying, extended channel etc., applicable to work with full power and half power switching, energy and consumption saving, sufficient drying and remarkable applicability.

4 With mesh-belt waste paper expelling device, enabling to improve security performance of the equipment and prevent print from damage by burning. (Expelling the paper dropped owing to abnormality of paper collecting chain and enabling to prevent thin paper from damage by burning.)

5 There is also decurler device available for customer’s choice. UV oil temperature preheating, circulating feeding, alternative modes of transport include electrical pump feeding or diaphragm pump feeding.

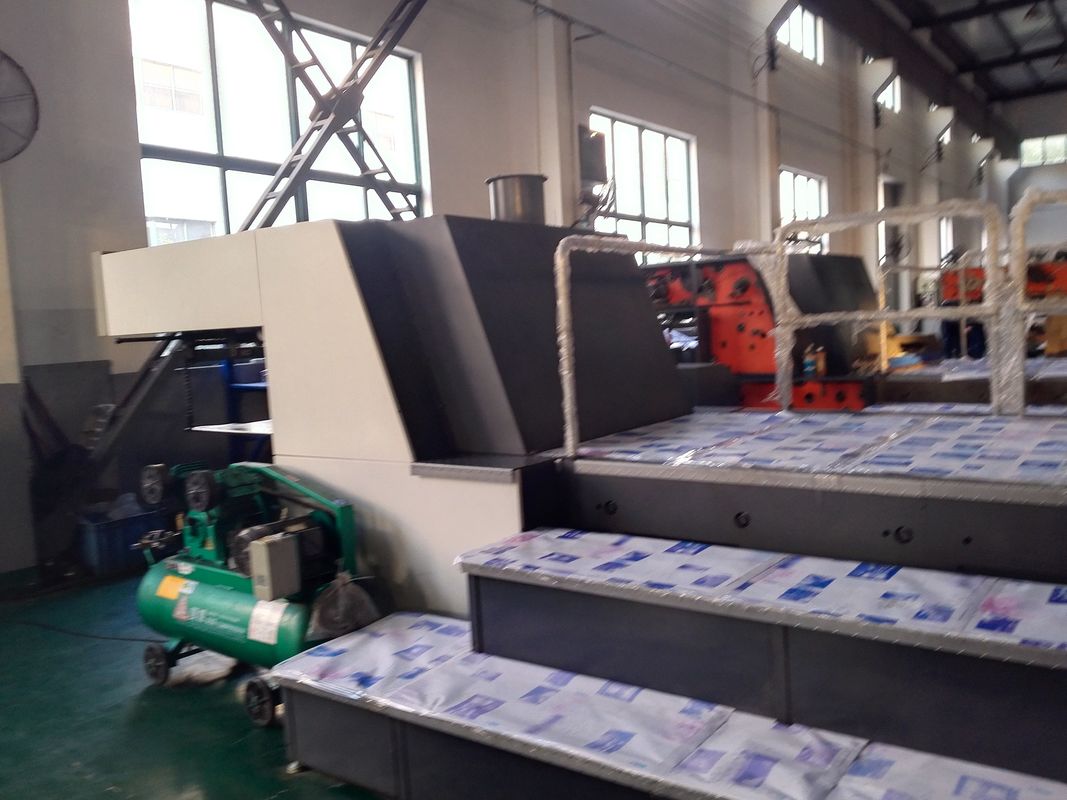

Details of Image

With continuous paper feeding and collecting function, easy for operation with high efficiency

Adopting some advanced oiling techniques such as anilox roller, chambered doctor blade system and etc, the evenness of oil layer is controllable with high gloss and without any dripping.

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!  आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए!

आपका संदेश 20-3,000 अक्षरों के बीच होना चाहिए! कृपया अपनी ईमेल देखें!

कृपया अपनी ईमेल देखें!